Development and maintenance of pumping stations: Development and maintenance of pumping stations. Design a gate guaranteed to operate all year round in any conditions. A glycol-heated gate operated using two independent lifting systems.

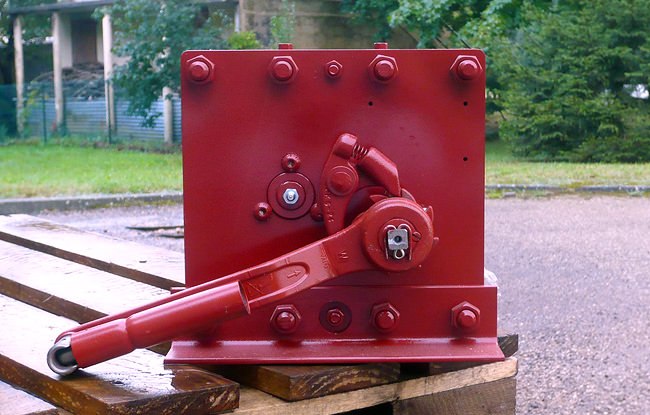

Dams often need spillway gates to evacuate spring floods as well as to divert water from the plant when the turbines are down. In this particular case, a canal brings the water from the river to the power station. Hence, it was essential that the bypass gate would operate at all times to ensure the safety of the residents upstream. Otherwise, any shutdown of the plant would result in a rapid increase in the water level and the flooding of several houses. Therefore, the first step was to ensure that the gate would be operable all year round, i.e. would not get stuck in ice. We installed a circulating glycol heating system. Piping in the concrete around the guides and the sill would prevent ice from forming. We also caped the downstream gate with metal plates and installed finned tubes to heat the enclosure. The outer wall would therefore remain above the freezing point. On the other side, the skin plate was insulated from the sill up to the water level. Then, we made sure the lifting system would never fail. In order to do that, we installed two independent operating devices: a hydraulic cylinder and pulley system and an electric winch. The winch is the primary system and winds the cable to raise the gate. If it does not work, the hydraulic system will extend the cylinders, tensioning the cable and raising the gate. Both systems can be combined manually to open the gate well above its normal position - above the concrete deck - to allow easy maintenance. The gate is also equipped with a second, smaller gate (called “pony gate”) that spills from the top. This allows to control the upstream water level and discharge any floating wastes that would otherwise remain in the canal.